YAMAWA - MH SERIES : For medium hardness carbon steel | JSR GROUP

MH SERIES

Ideal for medium hardness carbon steel machining.

The MH series demonstrates outstanding performance in machining internal threads and center holes in materials that have both strength and toughness.

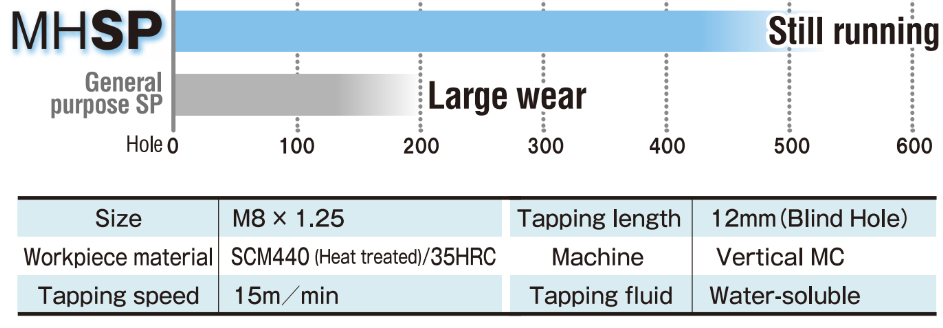

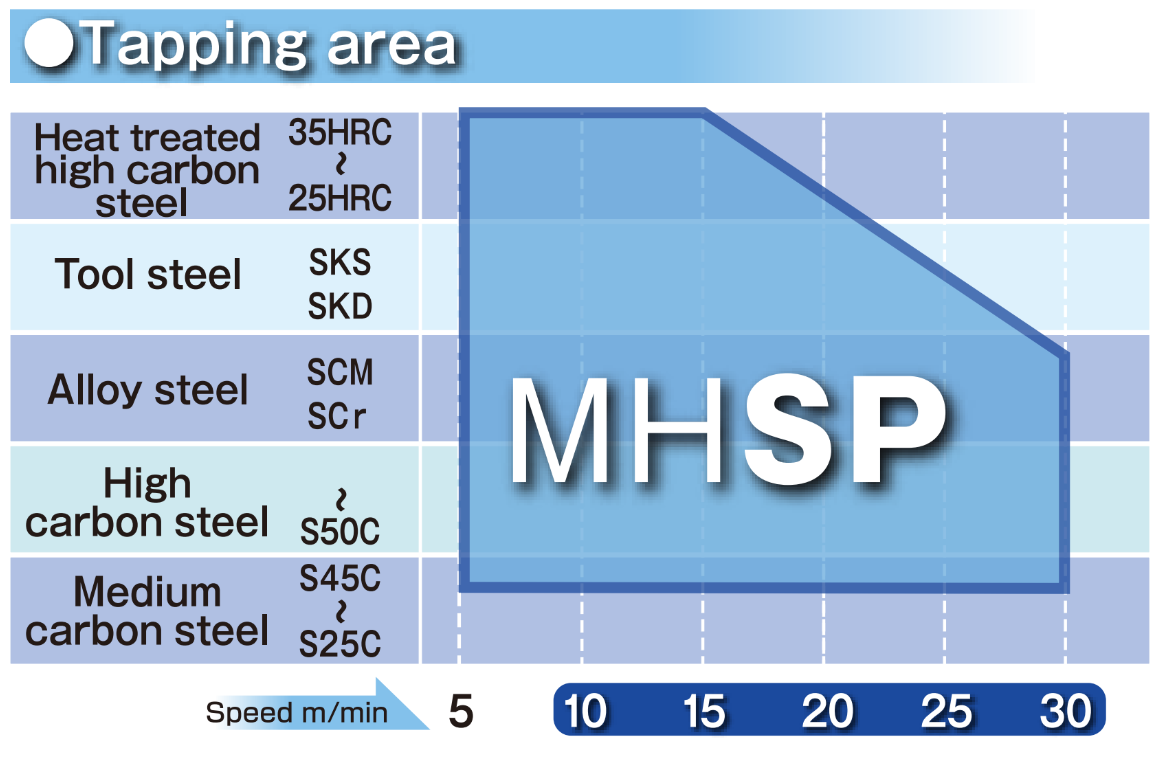

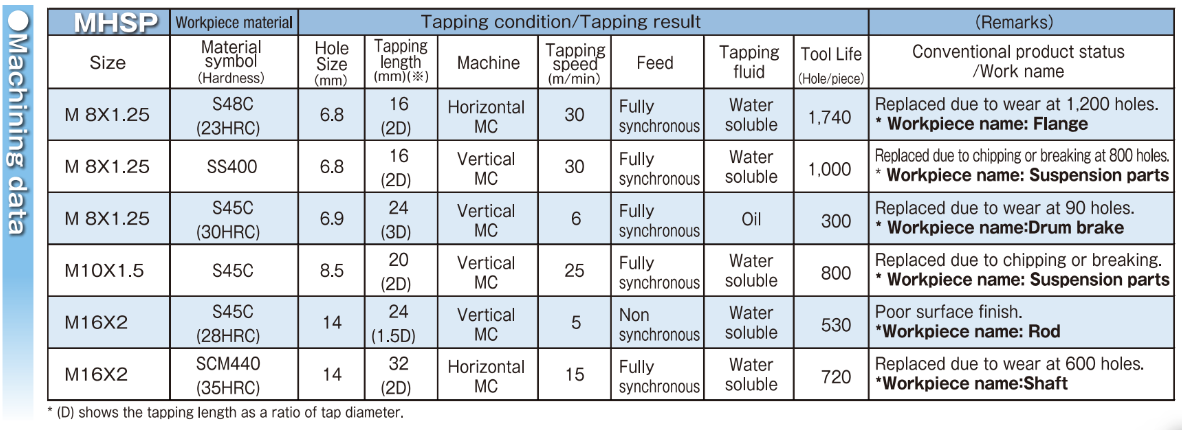

MHSP

Spiral fluted taps for blind holeS

When tapping blind holes in heat-treated parts, problems such as wear on the cutting edge or tap's damage by chip jamming are easy to occür, making stable machining difficult with general-purpose taps. MHSP was developed to solve these issues.

|

Recommended tapping speed is 5 to 30 m/min for medium and high carbon steel. 5-15m/min for medium hardness carbon steel |

|

1. Thread clearance from the middle of the tap helps to prevent chipping problems 2.The unique flute design produces a finely curled chip 3.Adopting full DIN length. |

Optimal coating Tool life increased Base material with excellent wear resistance

|

Outstanding chip evacuation performance

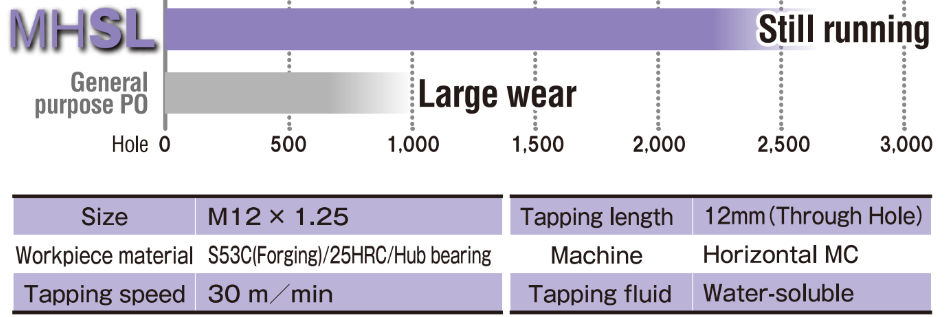

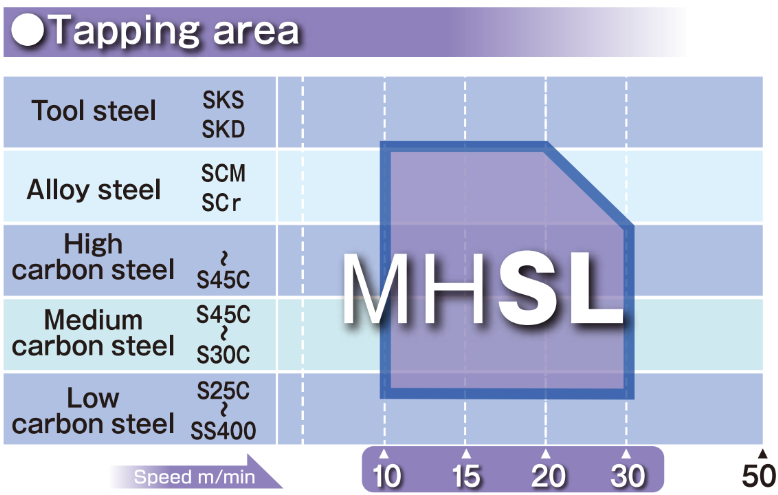

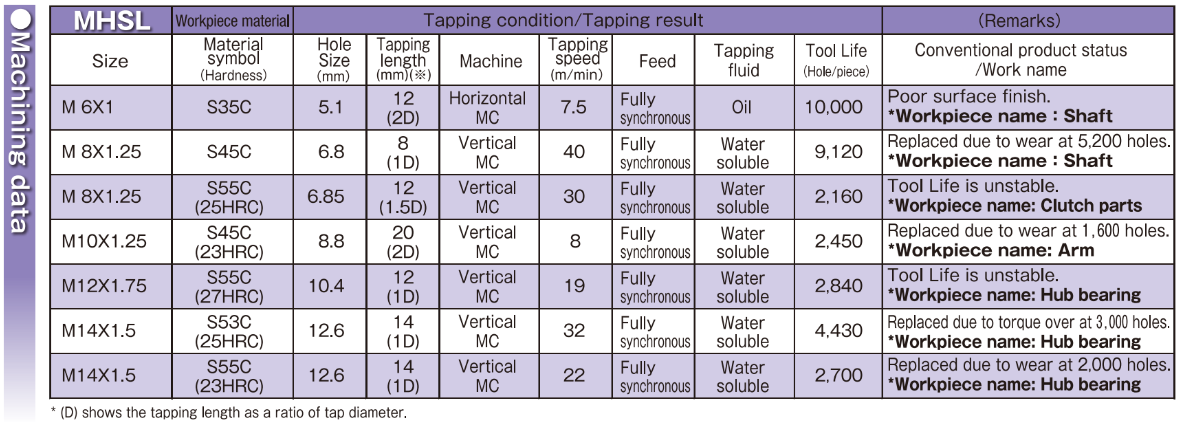

MHSL

Spiral fluted taps for through hole

In through hole tapping of heat treated medium hardness carbon steel, strength, rigidity, and durability are required. Many problems can occur such as wear of taps, chipped edges, and poor surface finish of internal threads. MHSL was developed to solve these tapping problems

|

Recommended tapping speed is 10~20m/min Base material has excellent durability and wear resistance. Adopting the optimum coating. |

|

1.Left handed flute with right hand cut pushes the chips forward 2.Two-stepped flute taper shape Improved chip evacuation performance. Chips are ejected in a uniform shape, which greatly reduces chipping problems. |

Outstanding durability

|

Outstanding chip evacuation performance

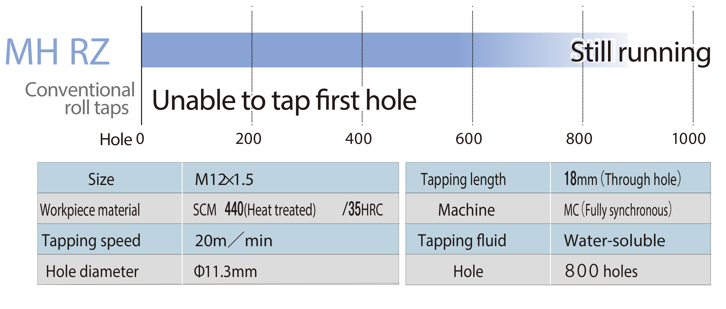

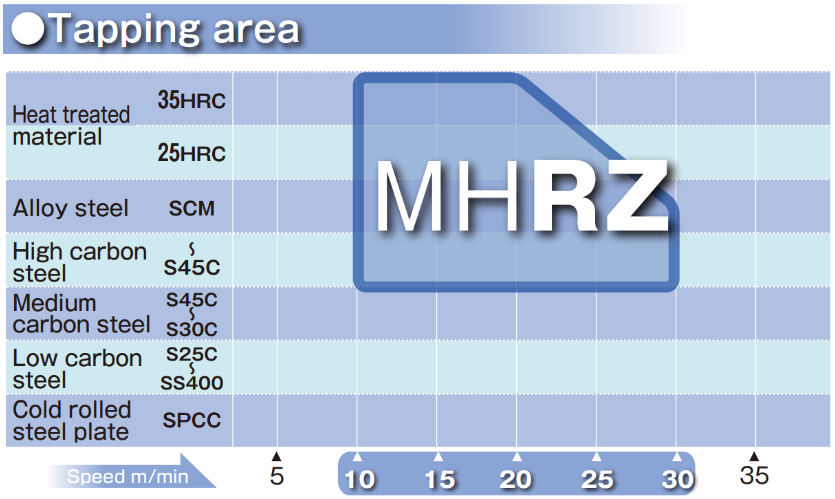

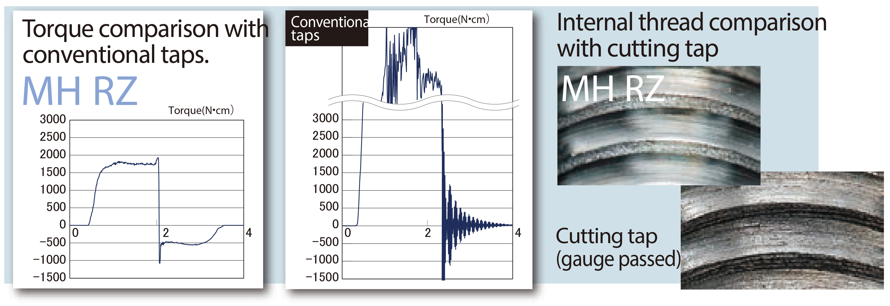

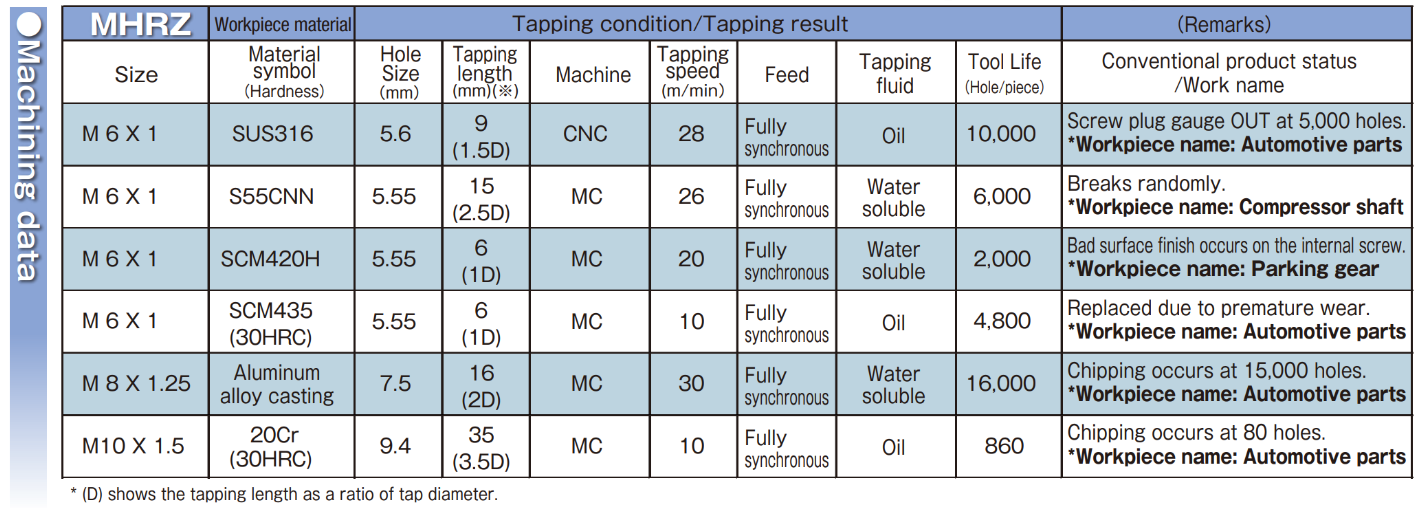

MHRZ

Roll taps

Roll form tapping on heat treated materials of 25 HRC or more has been considered difficult to achieve stable tapping due to high tapping torque. As a result MHRZ was developed.

|

Recommended tapping speed is 10 to 20 m/min for medium hardness carbon steel and alloy steel Adopting a base material with excellent durability and wear resistance.Adopting optimum coating. |

|

1. Originally developed thread part specifications. Success in reducing torque.

|

Extends tool life

|

Thread forming is now possible on medium hardness carbon steel with MHRZ

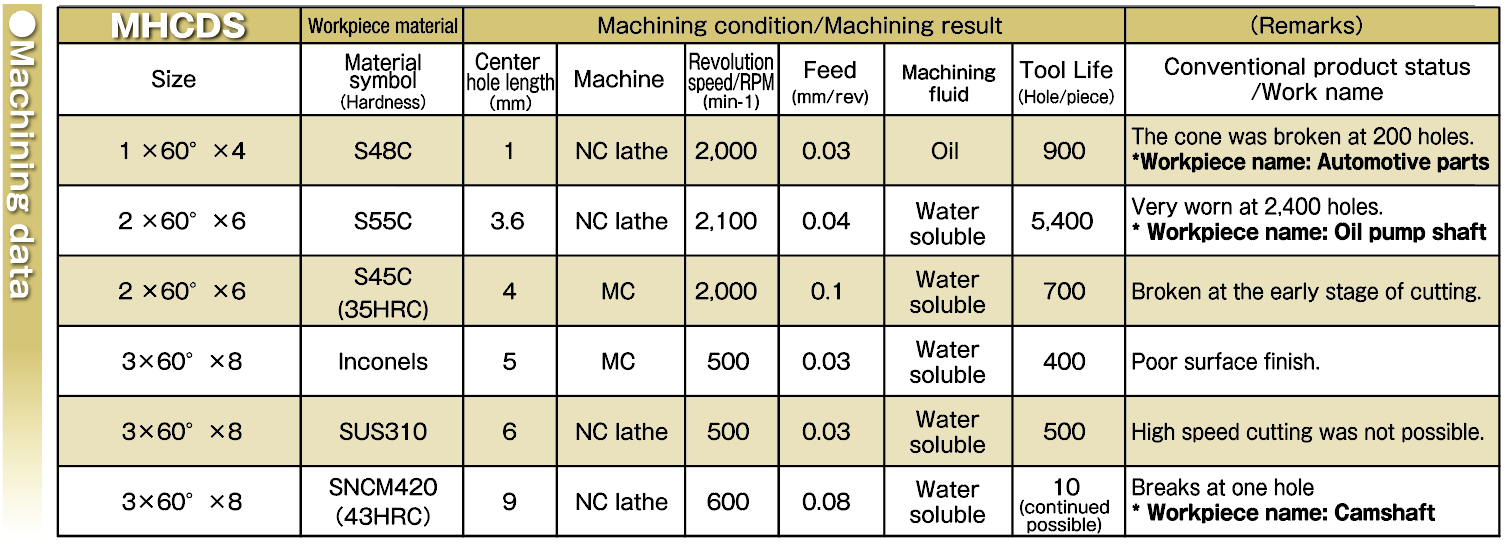

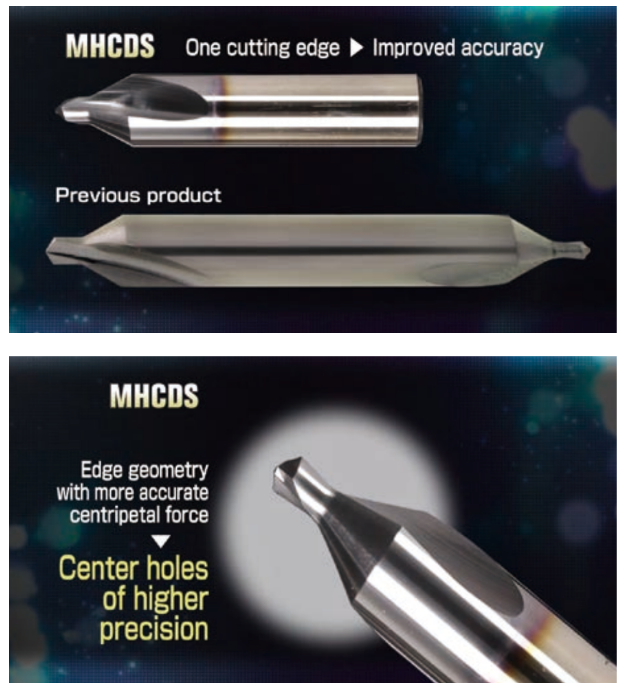

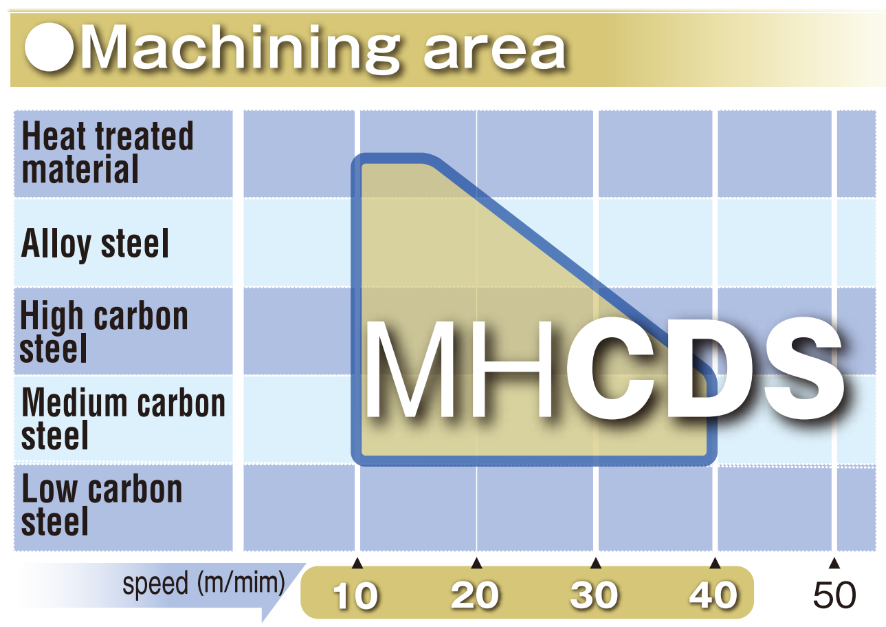

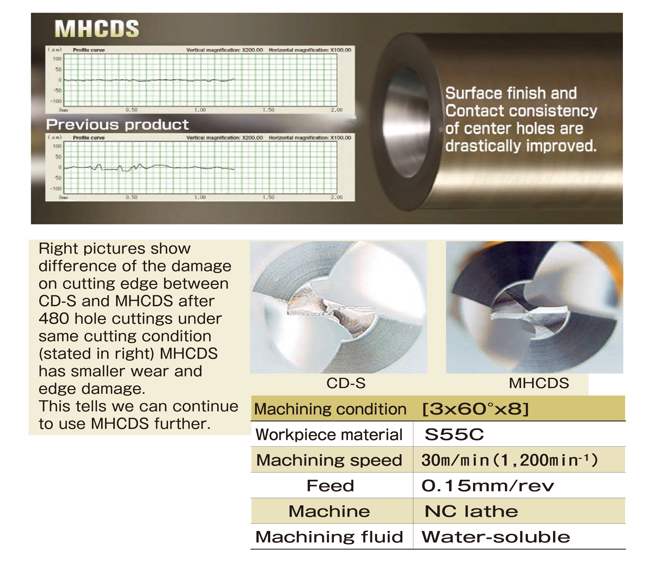

MHCDS

Center drills

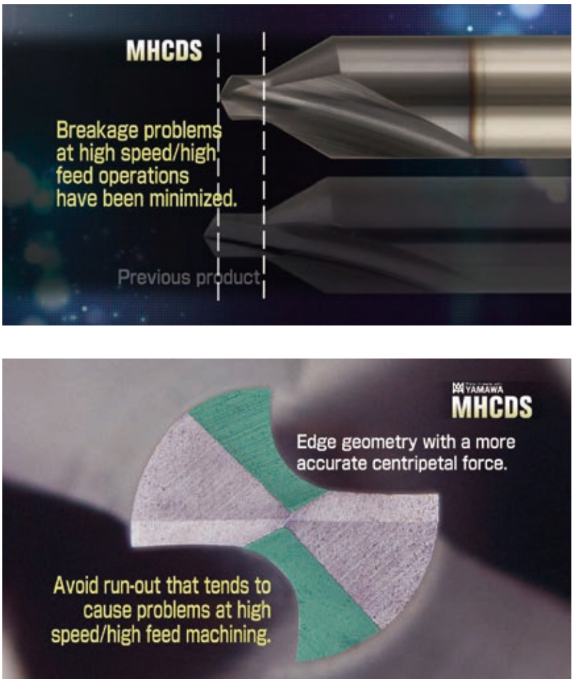

The center hole is the standard for cylindrical workpieces. The chamfered part of the center hole is infinitely round, and ideally there is no misalignment. At high speeds and feeds, runout problems are more significant. MHCDS was developed to combat these issues.

|

1.Highly accurate center holes can be machined with a single-ended shape and a special cutting edge design with high centrality.

|

Recommended machining speed is 20 to 30 m/min for medium hardness carbon steel and alloy steel, feed rate is 0.1 to 0.2 mm/rev. |

|

2.Ideal shape for high speed and feeds

|

Longer tool life, improved surface finish and roundness |

Produces reliable center hole machining in medium hardness carbon steel